Health4Cardio EE-LV00035

Period: 01.10.2023-30.09.2025

Programme priority: Jointly and smartly growing businesses

Specific objective: 2.1: Enhancing sustainable growth and competitiveness of SMEs and job creation in SMEs, including by productive investments

Summary

Health4Cardio is a cross-border cooperation project between BioCC OÜ (Estonia) and SISTEMU INOVACIJAS JSC – Si Biotech (Latvia). The project’s focus is to use cross-border knowledge transfer to improve the partners’ capacity to develop a prototype of an innovative new dietary supplement. The partners have their own individual strengths and expertise in production and distribution. BioCC works with high qualitative lactic acid bacteria cultures and is competent in conducting clinical trials with probiotics and functional foods, whereas Si Biotech is specialized in the extraction of natural substances using modern and green extraction methods, (CO2 supercritical fluid extraction) both for research and production. The common challenge is to find a technological solution to combine a clinically researched and patented probiotic bacteria strain with sea-buckthorn (Hippiophae rhamnoides) seed oil and find a suitable delivery form to determine health benefits for cardiovascular- and gut health.

Objectives

- Finding an innovative technology for the combination of two health-beneficial ingredients to develop a synergistic dietary supplement prototype using the in-house competencies of both partners.

- Determining the prototype’s mechanism of action and bioavailability by conducting a preliminary clinical trial.

Results

Completing these actions will create innovative technologies through sharing of knowledge and consequential product development. A jointly developed technology will raise both partners’ competitiveness and growth thanks to cross-border cooperation, knowledge transfer, and innovation.

Total budget: 577 375 €

Financed by the European Regional Development Fund (ERDF): 461 900€

Co-financed by the partners: 115 475€

Contact:

Liina Kuus

liina.kuus@biocc.ee

Report Period: 01.02.2024-31.05.2024

Work package 1

During reporting period Project activity – A1.1 “Product prototype development” was complated and A1.2 “Experimental production series and scale-up of production technology” was started.

Accordingly following activities where performed:

- review of scientific and technical literature on lipid and probiotic characteristics, properties and compatibility in homogenous solution;

- design of experimental approaches on how to successfully combine lipids with probiotics using mechanical and chemical technics;

- viability, compatibility and biological activity testing;

- specification of the new product in development;

- experimental production series simulation.

Another batch of si biotech sea buckthorn seed lipid extract (SBSLE) was produced exclusively for further developments in the scope of the Health4Cardio project. SBSLE was produced by supercritical fluid extraction with CO2, according to the company’s standard extraction procedure.

In order to develop a stable and biologically active combination of lipid extract with probiotics, it was decided to perform a gentle refinement procedure to purify SBSLE from free fatty acids, phospholipids, pigments, trace elements and oxidation products, which could reduce the viability of probiotics.

The leading partner provided its active ingredient for the combination – a patented probiotic strain, Lactobacillus plantarum Inducia, weight 200g, with a bacterial count of 5 billion CFU per gram.

After reviewing scientific and technical literature and analysing existing products in the market, considering Period 1 findings and conclusions, it was decided that the jointly developed product will contain 1000 mg of active ingredients—SBSLE, bacteria, and emulsifiers. The planned delivery form is a soft-shell capsule, the shell of which will consist of either fish gelatine or plant-based material.

To ensure repeatability, three separate attempts at experimental production were performed. Prepared samples were transferred to 50mL lab tubes. One set was stored at +4°C, the second in a dark, dry place at room temperature, and the third set was sent to leading partner BioCC for viability testing.

The combination’s homogeneity, sedimentation, and precipitation will be monitored, and adjustments in product specification will be made.

Total budget: 577 375€

Financed by the European Regional Development Fund (ERDF): 461 900€

Co-financed by the partners: 115 475€

Report No.3 project “Health4Cardio”, EE-LV00035, sibiotech

Report Period: 01.06.2024-30.09.2024

During report period (Period 3) Activity A1.2 – “Experimental production series and scale-up of production technology” was implemented as wel as Activity A1.3 – “Newly developed product safety and efficiency assessment” was started. Following tasks where performed:

- The optimisation of advanced technological methodologies for the refinement of sea buckthorn seed lipid extract.

- The evolution of the most effective technological strategies for ensuring ingredient compatibility, stability, and preservation of biological activity.

- The assessment of probiotics viability within homogenised suspensions.

- A comprehensive analysis of the fatty acid profile in homogenised suspensions.

- The development and scaling of an optimised manufacturing process.

Besides, following experimental tasks where performed:

sibiotech sea buckthorn seed lipid extract (OHS01) was obtained according to the protocols outlined in WP2. The refinement process was further enhanced through modifications, wherein the lipid extract underwent advanced filtration, sedimentation, and bleaching techniques. These adjustments were designed to optimise the fatty acid composition while minimising oxidative degradation of the oil.

The purified sea buckthorn seed lipid extract was then homogenised with soy lecithin and Lactobacillus plantarum, using five distinct emulsifier concentrations, along with varied durations and rotational speeds (RPM) during the homogenisation process.

- Filtration procedure: the oil was initially heated to +50°C on a magnetic stirrer under constant rotation. It was then gradually cooled before being stored at +5°C for 24 hours. The filtration process extended over five days, with a progressive reduction in filter pore size: 25 µm on day 1, 15 µm on day 2, and 5 µm from day 3 to day 5 (Figure 1A).

- Sedimentation procedure: ethanol (96%) was added to the filtered lipid extract in a solvent-to-oil ratio of 1:2 and mixed for 30 minutes under vacuum conditions at +30°C. The resulting mixture was then transferred to separation funnels and allowed to separate for 24 hours at +5°C (Figure 1B). The lower phase, containing the lipid extract, was carefully collected, and the residual solvent was removed via rotary evaporation, following standard protocol (+40°C, 130 RPM).

- Bleaching procedure: activated bleaching earth clay, at a concentration of 1%, was added to the evaporated lipid extract. The mixture was subjected to vacuum conditions, stirred at 100 RPM, and heated to +70°C for 30 minutes. Subsequently, the mixture was filtered twice using 5 µm filters to collect the purified oil fraction.

Figure 1. Oil purifying process. A – filtration of the oil; B – sedimentation of the oil.

The chemical content analysis of the bleached oil (Table 1) revealed that the purification method effectively reduced the concentration of free fatty acids (FFA), which are stored in triglycerides (GCL). Since free fatty acids are more prone to oxidation, their reduction significantly enhances the oil’s oxidative stability, helping to prevent rancidity and maintain the oil’s quality.

Table 1.

Fatty acid composition of the bleached oil

| Fatty acid | GCL mg/g | FFA mg/g | Total mg/g | % |

| Palmitoleic acid C16:1n-7 | 6,5 | 0,7 | 7,2 | 1,05% |

| Palmitic acid C16:0 | 59,4 | 2,7 | 62,1 | 9,08% |

| Linoleic acid C18:2n-6 | 275,9 | 5,7 | 281,6 | 41,17% |

| Oleic acid C18:1n-9 + Linolenic acid C18:3n-3 | 299,1 | 4,8 | 303,9 | 44,43% |

| Stearic acid C18:0 | 28,1 | 1,1 | 29,2 | 4,27% |

| TOTAL, mg/g | 669 | 15 | 684 | 100,00% |

4. Preparation of the emulsifier: in contrast to the method outlined in WP2, soy lecithin was used as an emulsifier to achieve a homogeneous mixture. A small quantity of lecithin was incorporated into the purified oil, and the mixture was heated to +40°C under constant stirring until the lecithin fully dissolved (Figures 2A and 2B). Five samples with varying lecithin concentrations were then prepared (Figure 2C). Following this, L. plantarum was added into the oil-lecithin mixture.

Figure 2. Lecithin-oil mixture preparation. A – pure oil; B – oil with lecithin; C – five samples prepared.

The recommended concentration of lecithin 0.1% – 0.3%; samples:

- 5 x 109 CFU* + 100 g of lipid extract + 0.1% soy lecithin

- 5 x 109 CFU* + 100 g of lipid extract + 0.5% soy lecithin

- 5 x 109 CFU* + 100 g of lipid extract + 1.0% soy lecithin

- 5 x 109 CFU* + 100 g of lipid extract + 1.5% soy lecithin

- 5 x 109 CFU* + 100 g of lipid extract + 2.0% soy lecithin

*5 x 109 CFU +20% in order to confirm final dosage contains 5 x 109 CFU live Lactobacillus plantarum

5. Homogenisation procedure: a high-shear mixer was used to mix the oil and bacteria, following the methodology outlined in WP2 (Figures 3A, 3B and 3C). However, the samples were subjected to five varying homogenisation times and rotational speeds (RPM) to optimise the process:

- A. 5000 RPM / 2 min

- B. 5000 RPM / 3 min

- C. 7500 RPM / 2 min

- D. 7500 RPM / 3 min

- E. 7500 RPM / 5 min

Figure 3. High-shear homogenisation process. A – L. plantarum added to the sample; B – High-shear homogenisation; C – vacuuming process of the sample.

The samples were collected (Figure 4) and stored for future analysis of the bacteria viability and stability tests.

Figure 4. Samples for the further analysis.

6. Scale-up process: the homogenisation process was scaled up to handle 500 g of lipid extract, using 2.0% soy lecithin and high-shear homogenisation at 10 000 RPM for 7 minutes (Figure 5A). The vacuuming step was conducted using an advanced evaporation system (Figure 5B). The resulting sample was then stored for subsequent analysis (Figure 5C).

Figure 5. Scale-up process. A – high-shear homogenisation; B – vacuuming process; C – the sample of 500 g of the suspension.

Following the successful scale-up to 500 g of raw material, the process was further expanded to 5000 g (Figure 6) in preparation for trial batch manufacturing aimed at product encapsulation in soft-shell capsules. The initial product specification has been established, and a comprehensive documentation package, including the MSDS, product specification, encapsulation specification, and Certificate of Analysis (CofA), has been compiled to facilitate the ordering of the trial encapsulation batch (Table 2).

Table 2.

Specification of the product

| Product: | Sea buckthorn seed oil (scCO2) with Lactobacillus plantarum |

| Appearance: | Oblong transparent soft gelatine capsule |

| Average fill weight: | 1000,00 mg ± % |

| Best before: | |

| Ingredients of the capsule filling | |

| Capsule fill total amount | 1000,00 mg |

| Sea buckthorn seed oil (scCO2) | 988,00 mg |

| Microencapsuled Lactobacillus plantarum (5×1011 CFU/g) | 10,00 mg |

| Sunflower lecithin | 2,00 mg |

| Trace amounts of: Calcium chloride, sodium alginate. | |

Figure 6. Equipment for trial batch manufacturing, including refinement – neutralisation, bleaching and filtration, vacuum homogenisation oil with bacteria using an emulsifier.

Report No.4 project “Health4Cardio”, EE-LV00035, Sibiotech

Report Period: 01.10.2024 – 31.01.2025.

Activities performed during this period:

- A stability testing plan was developed in compliance with ICH guidelines.

- Final product samples were prepared and baseline tests were conducted.

- First tests was performed to monitor probiotic viability and fatty acid stability of the samples stored in various stability zones.

- A set of clinical trial documentation was created.

Tasks performed during the activity period:

1. Design and execution of the stability testing plan

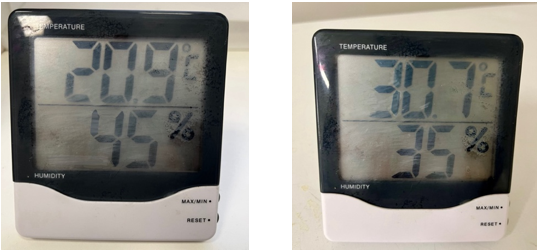

A comprehensive stability testing plan was developed to ensure that the product would maintain its quality and efficacy throughout its shelf-life. The plan specified testing intervals for 6 months. The environmental conditions were aligned with ICH stability zones (using temperature and humidity sensors):

- Zone I: 21°C / 45% RH.

- Zone II: 25°C / 60% RH.

- Zone III: 30°C / 35% RH.

- Zone IVa: 30°C / 65% RH

- Zone IVb: 30°C / 75% RH.

- Accelerated conditions: 40°C / 75% RH.

Figure 1. Temperature and humidity sensors. On the left – zone I; on the right – zone III.

The plan also established acceptance criteria for key parameters, such as probiotic viability (maintaining 5 x 10^9 CFU/g), fatty acid stability (allowing less than a 5% variation in major fatty acids), and oxidative stability (keeping thiobarbituric acid reactive substances (TBARS) levels below 2.0 MDA µmol/kg.

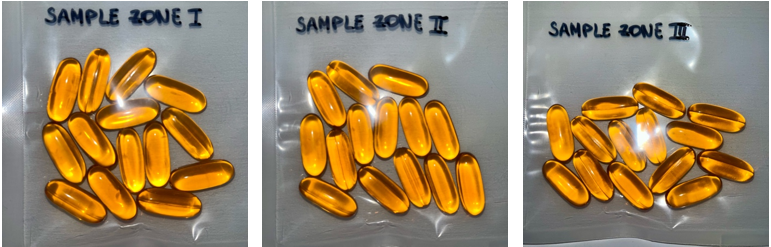

2. Preparation and storage of stability samples

Next, the preparation and storage of stability samples were conducted. The finalized product was encapsulated in soft-shell capsules using a semi-manual process for the trial batch. The capsules, made from fish gelatin, glycerin and water, contained sea buckthorn seed oil (scCO₂), sunflower lecithin and Lactobacillus plantarum. Each batch of capsules was carefully stored in stability chambers, where temperature and humidity were controlled to replicate the designated stability zones. Initial observations confirmed the homogeneity of the capsules, with no phase separation detected.

3. Baseline and periodic testing

Baseline testing was performed on prepared samples to establish initial values for probiotic viability, fatty acid composition and lipid peroxidation. The baseline CFU counts indicated that Lactobacillus plantarum was present at 5 x 10^9 CFU/g, confirming the initial viability of the probiotics. The fatty acid profile, analyzed through gas chromatography, revealed concentrations of key acids: approximately 41% linoleic acid, 45% oleic acid, 9% palmitic acid, 4% steraic acid and 1% palmitoleic acid. The TBARS assay results demonstrated low initial levels of oxidation, with MDA concentrations at 1.2 µmol/kg.

Next, first stability tests were conducted for an initial period of a month, with weekly checks.

4. Analysis of fatty acid composition

Fatty acid profiles were monitored to detect degradation of unsaturated fats. The fatty acid composition was analyzed using gas chromatography. The analysis aimed to detect any significant changes in the fatty acid profile, particularly focusing on the degradation of unsaturated fatty acids prone to oxidation. By the end of the month, samples stored in accelerated conditions showed a slight increase in peroxide value, indicating early oxidation, while the overall composition remained within acceptable variation limits, with less than a 5% change in major fatty acids.

5. Lipid Peroxidation Monitoring

The monitoring was performed using the TBARS assay to assess oxidative stress in the lipid samples. This process involved heating the samples with thiobarbituric acid (TBA) under acidic conditions, which allowed the malondialdehyde (MDA), a byproduct of lipid peroxidation, to react with TBA and form a colored complex. The intensity of the resulting color was measured spectrophotometrically, providing an indication of the extent of lipid peroxidation.

Zone I – IVb samples remained stable at 1.2 MDA µmol/kg, while accelerated condition samples approached the threshold with 1.6 MDA µmol/kg by the end of the period.

6. Compilation of Stability Data and Reporting

All results from the tests will be documented, highlighting trends in probiotic viability and fatty acid stability. This data will be compiled into a technical dossier, which will be including detailed findings on the stability of probiotics, fatty acids, and oxidative levels, supporting the next steps in the product development process.

7. Clinical trial documentation.

During this reporting period, we’ve completed several crucial steps in preparing for our clinical study of the sea buckthorn oil and probiotic supplement. Activities accomplished:

Initial Protocol Development:

We’ve created a comprehensive study protocol (H4C/2025) that outlines our investigation into how our previously designed formulation – combination of sea buckthorn seed oil and L. plantarum INDUCIA® might affect study participants who daily use probiotic supplements. We are intended to access if our formulation can improve cholesterol metabolism, oxidative stress markers, clinical blood parameters, and gastrointestinal microbiota in individuals with elevated cholesterol levels. The protocol details everything from the scientific reasoning behind our study to the practical steps of how we’ll conduct it.

Study Population Planning:

We’ve defined who can participate in the study. We’re aiming for 50 participants, setting clear guidelines about who can join and who shouldn’t. We,ve developed an inclusion/exclusion criteria list, that helps ensure our results will be meaningful and our participants will be safe.

Measurement Framework:

We’ve established what we’ll be measuring and how. This includes detailed blood tests for cholesterol levels, analyses of gut bacteria, and various other health indicators. We’re collaborating with laboratories in both Latvia and Estonia to get a complete picture of how the supplement affects participants’ health.

Practical Implementation Plan:

During the reporting period, we have successfully assembled a comprehensive research team that combines academic expertise with clinical experience. The team structure includes:

Core Research Team:

Ēriks Jakobsons, Mg. biol (Institute of Cardiology and Regenerative Medicine) – Study coordination and Latvia-Estonia collaboration

Supporting Clinical Staff:

Clinical physicians for patient screening and follow-up and experienced nursing staff for blood sampling and clinical measurements

Each team member has been assigned specific responsibilities aligned with their expertise, ensuring efficient study implementation and quality data collection. The team structure supports both the scientific rigor required for the research and the practical aspects of clinical trial execution.

We’ve mapped out exactly how the study will run, including schedule of visits for each participant, specific tests and measurements at each visit, clear procedures for handling samples and data. We’ve developed a simple but effective two-visit approach to track our supplement’s effects:

First Visit (Baseline):

- Complete health assessment and measurements

- Collection of blood and stool samples

- Supplement distribution with usage instructions

- Two capsules daily for 6-8 weeks

Follow-up Visit (Week 6-8)

- Repeat health assessment and measurements

- Collection of follow-up samples

- Evaluation of supplement use and any effects

Both visits include laboratory analyses at Latvia and Estonia facilities, with phone follow-up to monitor participant progress and provide needed guidance. Timeline running from April to October 2025.

Risk Assessment and Management:

We’ve conducted a thorough analysis of potential risks – from financial concerns to practical challenges – and developed strategies to address them.

Data Protection Framework:

We’ve established secure systems for handling participant personal (sensitive) information, ensuring compliance with privacy regulations while maintaining research integrity.

Ethics and Documentation:

We’ve prepared all necessary documentation for ethics approval and participant consent, prioritizing clear communication and participant safety.

All these elements work together to create a solid foundation for our research. They ensure we’ll be able to conduct a study that’s both scientifically rigorous and practically feasible, while maintaining the highest standards of patient care anddata integrity.

Report No.5 project “Health4Cardio”, EE-LV00035, Sibiotech

Report Period: 01.02.2025. – 31.05.2025.

Activities performed during this period:

- The stability testing was continued in compliance with ICH guidelines to monitor probiotic viability and fatty acid stability of the samples stored in various stability zones.

- The final clinical trial documentation file was created.

- The Ehics approval application was submitted and appropriate approval was received.

- The guidlines for patient information, study subject enrollment, biological material sampling and handling were developed.

- Training program for medical staff involved in clinical trial was developed.

- An exhibition CPHI Japan (Tokyo) in Japan was attended to present jointly developed product.

Participation in CPHI Japan (Tokyo)

From April 9-11, 2025, síbiotech took part in CPHI Japan, one of Asia’s largest pharmaceutical and biotech exhibitions, held in Tokyo Big Sight. During the exhibition, we presented SIBIOTECH’s portfolio and highlighted our latest developments in the field of innovative biotechnological products. During the event, we presented our range of Omega-3 fatty acids and powerful antioxidants—nature’s own health boosters—to industry leaders and wellness innovators from around the world.

The exhibition also provided an excellent opportunity to introduce a new product developed in collaboration with our Estonian colleagues (BioCC OÜ) within the framework of the Cardio4Health project. This unique formulation combines Omega-3 fatty acids, plant sterols, and probiotic bacteria to support cardiovascular health and maintain gut microbiota balance. The active ingredients are obtained using supercritical CO₂ extraction, ensuring exceptional purity and bioavailability.

The event provided excellent opportunities for networking with potential partners, distributors, and industry stakeholders from Japan and other international markets.

Visit to EXPO 2025 (Osaka)

As part of the business program, we also visited EXPO 2025 Osaka, where we explored current trends and innovations in sustainability, health, and biotechnology. The visit provided valuable insights and inspiration for future product development and potential collaboration within the Japanese and broader Asian markets.

Business meetings in Osaka

During the trip, síbiotech’s team held presentation for local companies in Osaka. We introduced síbiotech’s innovative product line, the product manufacturing capabilities, and shared information about our sustainable production approach. The meetings sparked genuine interest from local partners, opening perspectives for potential future cooperation and market entry opportunities.

Communication materials prepared for the visit

For this Japan business trip, síbiotech made a focused effort to prepare comprehensive marketing and communication materials tailored for the Japanese market. Special emphasis was placed on promoting the products developed within the framework and financial support of the INTERREG project Cardio4Health.

As part of the preparation, we developed:

- brochures in English and Japanese,

- product visual identity and packaging design,

- product labels and packaging in English and Japanese,

- a presentation about our products and production facilities,

- an informative video introducing the company and our production process.

The professional presentation materials were highly appreciated by local stakeholders and contributed to the positive reception of our products during the meetings.

Outcomes and perspectives

The visit to Japan has helped to develop síbiotech’s visibility in the region and helped establish valuable contacts with potential partners. The positive feedback and interest from local businesses create promising prospects for future collaboration and market expansion in Japan and the wider Asia-Pacific region.

Contact:

Liina Kuus

liina.kuus@biocc.ee